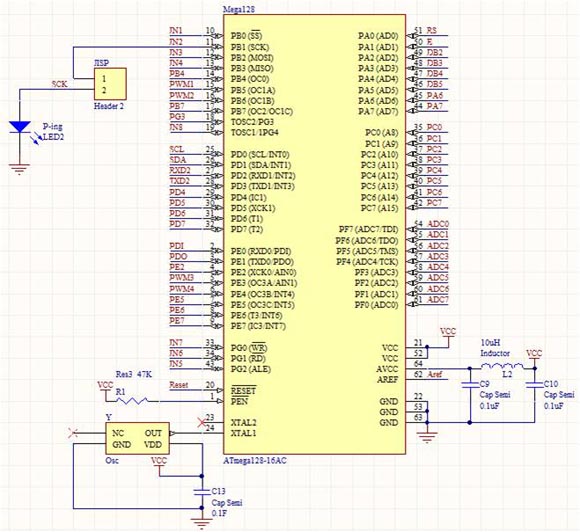

Since the instruction set of AVR highly corresponds to the C Language,

I choose

AVR-GCC

, the GNU C Compiler for AVR, to compile my programs for its characteristic of free software

and high compiling efficiency. In addition, GCC also supports other structures such as ARM,

DSP, and X86; therefore, learning AVR-GCC lays the foundation for studying the usage of

other devices afterwards.

Because AVR-GCC is not released with any integrated

development environment (IDE), I pick a third-party IDE called

Win-AVR

to develop software.

Due to the property of my driver programs, the user code should

be written in a foreground-background processing structure; thus, an endless loop should

serves as the stem of the program – the background – while the interrupt routines – the

foreground – provide the data from hardware modules.

The driver provides standard C

Language functions to control hardware modules including I2C, USART, ADC, timer/counter (T/C)

, etc. as well as peripheral devices such as digital compass, DC motors, LCD, etc. It also

gives users the right to monitor all ADC ports after initializing hardware resources and

before running user code.